Let’s Understand About Resin Infusion in Composite Industry

With the advancement in technology, the composite industry always has an ever-increasing demand for faster production rates while maintaining the quality of the material. Undoubtedly, composite materials have revolutionized numerous complex industries by offering a reliable combination of strength, durability, and lightweight properties. As we all know composite materials are formed with the help of several effective techniques to ensure their unique properties. Among the various manufacturing techniques, resin infusion is widely known for its versatility and efficiency. The technique is used to produce composite materials with high accuracy and repeatability along with complex geometries.

Although resin infusion and vacuum bagging are similar kind of process, the only difference is that the fabric piles are placed in the mould dry and remains dry while the vacuum bag is assembled. Resin Infusion is the best option when producing composite materials for large structures and the technique is also cost effective. With the help of this process, the manufacturers can easily achieve exceptional laminate properties. In this blog post, we will gain in-depth knowledge of resin infusion, its advantages, and applications.

The most crucial part of the process is evacuation or we can say removal of air from the reinforcement before pouring resin in it. The air needs to be removed so that the resin can take its place to form a reliable composite material. This process can also be done by incorporating roll wrapping for even better results.

Not only the technique is cost-effective, but if used correctly, it can produce composite materials with unbeatable strength and quality appearance. As the process takes place in a sealed bag and a mould that is in a closed environment, it further ensures the low emission of volatile materials to the environment and thus provides sustainable manufacturing solutions. With the help of infusion, the number of components required to make a part is slightly reduced.

Resin Infusion is indeed an integral part of the composite manufacturing industry. With its ability to produce materials with versatility, durability, and adaptability, the technique is greatly used in numerous complex industries. Want to know more about resin infusion or similar techniques in detail? Datum Advanced Composite is your one-stop solution!

Although resin infusion and vacuum bagging are similar kind of process, the only difference is that the fabric piles are placed in the mould dry and remains dry while the vacuum bag is assembled. Resin Infusion is the best option when producing composite materials for large structures and the technique is also cost effective. With the help of this process, the manufacturers can easily achieve exceptional laminate properties. In this blog post, we will gain in-depth knowledge of resin infusion, its advantages, and applications.

What is Resin Infusion?

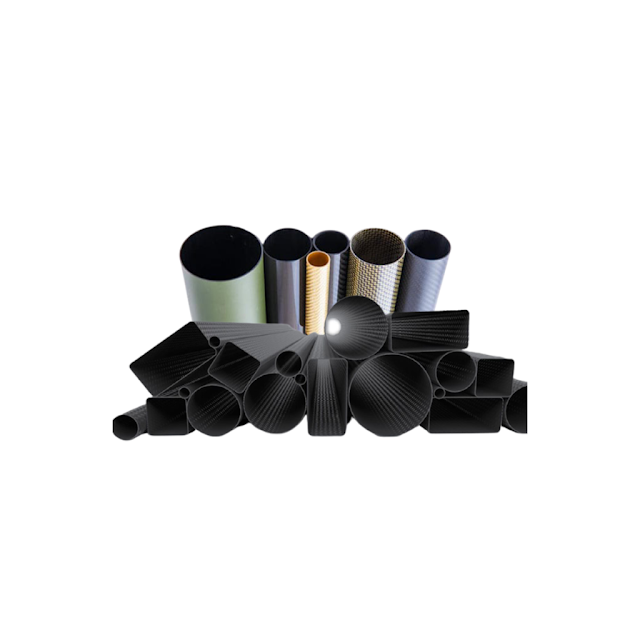

It is one of the most crucial composite manufacturing processes in which the liquid resin is infused into a dry fiber reinforcement which further results in producing a strong and light-weight composite material. The key components utilized in this technique include a mould, dry reinforcement such as fiberglass or carbon fiber, and a liquid resin system. Typically, resin has a two-part system namely base resin and hardener which react to form a solid material.The most crucial part of the process is evacuation or we can say removal of air from the reinforcement before pouring resin in it. The air needs to be removed so that the resin can take its place to form a reliable composite material. This process can also be done by incorporating roll wrapping for even better results.

Advantages of Resin Infusion in Manufacturing Composites

Not only the technique is cost-effective, but if used correctly, it can produce composite materials with unbeatable strength and quality appearance. As the process takes place in a sealed bag and a mould that is in a closed environment, it further ensures the low emission of volatile materials to the environment and thus provides sustainable manufacturing solutions. With the help of infusion, the number of components required to make a part is slightly reduced.

Applications of Resin Infusion

In the world of advanced composite manufacturing, resin infusion plays a crucial role by offering versatile and reliable materials cost-effectively. Because of its ability to produce lightweight and strong composite materials, the technique is used to manufacture parts in various complex industries.Aerospace Industry

One of the major sectors that the technique is used widely is the aerospace industry. The aerospace sector demands materials that have both lightweight and robust properties. To achieve this, manufacturers utilize resin infusion technique to manufacture structures having excellent strength-to-weight ratios to enhance the overall performance of aircraft.Wind Energy

The renewable energy or wind energy sector greatly embraces this technique to manufacture wind turbine blades. Perfectly incorporated with vacuum bagging, the technique can produce composite materials with high strength and durability.Marine Industry

Not only the high strength and durability, the technique also ensures the corrosion-resistant properties of composite materials. This property is highly appreciated in the marine industry. Additionally, the lightweight nature of these components contributes to fuel efficiency and high performance.Automotive Sector

The automotive sector utilizes the technique of roll wrapping to produce strong and lightweight components for body panels, chassis parts, and other interior components. It contributes to fuel efficiency and reduces emissions.Sporting Equipment

Undoubtedly, sporting equipment needs to be lightweight and strong to enhance the performance of athletes. As the resin infusion technique can produce goods with such unique properties, it is widely famous in the sports industry as well.Resin Infusion is indeed an integral part of the composite manufacturing industry. With its ability to produce materials with versatility, durability, and adaptability, the technique is greatly used in numerous complex industries. Want to know more about resin infusion or similar techniques in detail? Datum Advanced Composite is your one-stop solution!

Comments

Post a Comment