Let’s Understand About Resin Infusion in Composite Industry

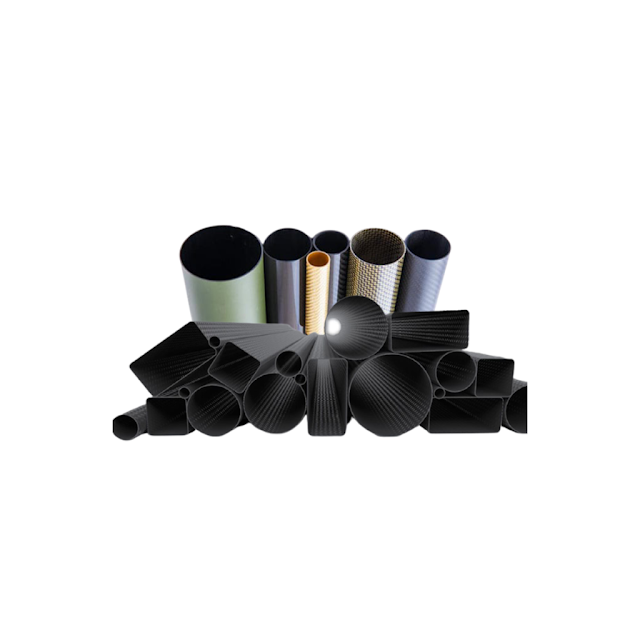

With the advancement in technology, the composite industry always has an ever-increasing demand for faster production rates while maintaining the quality of the material. Undoubtedly, composite materials have revolutionized numerous complex industries by offering a reliable combination of strength, durability, and lightweight properties. As we all know composite materials are formed with the help of several effective techniques to ensure their unique properties. Among the various manufacturing techniques, resin infusion is widely known for its versatility and efficiency. The technique is used to produce composite materials with high accuracy and repeatability along with complex geometries. Although resin infusion and vacuum bagging are similar kind of process, the only difference is that the fabric piles are placed in the mould dry and remains dry while the vacuum bag is assembled. Resin Infusion is the best option when producing composite materials for large structures and the techni...