Why is Finite Element Analysis the Future of Engineering?

As time is moving forward, innovations are shaping the future across industries. The companies are more concerned & thrilled about their product development than before. They want to make sure that whatever they craft outshines others in the market. In the engineering domain, the game is no different. Today, developing marvellous products like the Boeing 787 Dreamliner is made easy through finite element analysis (FEA).

A massive aircraft that boasts a 50,000 hp engine and is composed of 18,000 different parts feels surreal. But that is possible today with the help of the right technology and methodologies. Apart from the industry's best techniques, one thing that’s ironic is the FEA. Due to its capabilities of analysing the product design without even building a prototype is a mastermind move. In this article, we will learn what FEA is and how it will shape the future of engineering across industries.

What is Finite Analysis?

The reason that FEA holds infinite importance is because of its capabilities to study a complex design and provide detailed information about the robustness and efficiency of that design. It helps engineers become aware of improper design techniques and system failures without actually making the product. Composites design and engineering often require this method to analyse how the chemical properties of two different products will behave on combining them.

How Does the FEA Method Work?

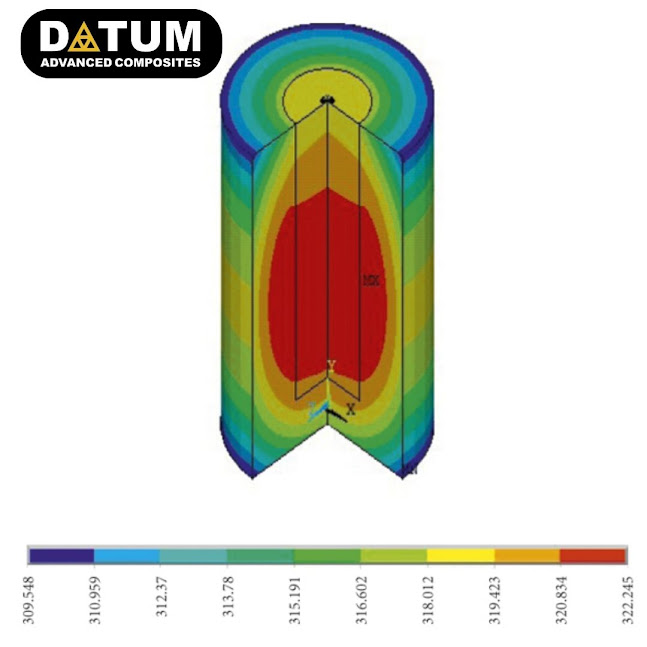

The FEA includes developing a digital mesh of the design. This constructed design includes multitudinous smaller elements which are referred to as the finite elements. Afterwards, the data for each of those finite elements is then mapped. The mapping results in breaking down a large equation into multiple tinier equations for each of those elements. These equations are then given a picture of the dynamics acting on a design by combining them together.

Such kind of mathematical modelling and calculation usually requires partial differential equations which hold immense importance in analysing the overall design process. All these smaller partial differential equations are further broken down into simpler algebraic approximations using the FEA.

This method of calculative analysis empowers engineers to modify the prediction accuracy of the complex product design so that they can accurately concentrate on the core complication. It allows them to analyse the structure and stresses acting on a particular part of the product.

How can FEA Shape the Future of Engineering?

It is true that FEA is shaping the future of engineering in different verticals and is the stand-alone future methodology that will help develop some futuristic products in the coming years. However, FEA is not a new concept or method, it has been in existence since the 1960s. With time and the development of new technologies, the ways to use this method have been modified. Today it is used in the marine, aerospace, automotive, and construction sectors to name a few.

For instance, the renowned automobile company, Rolls-Royce uses the FEA in addition to computer aided designing (CAD) to craft their marvellous and high-tech four-wheelers. It is because the nature of FEA allows them to take calculated risks during the production process. It allows them to test the complex geometry, multiple material types and the capability to capture the local stresses acting on the minute areas of the design.

The future of engineering in almost all industries belongs to finite element analysis, especially in those verticals where the cost of manufacturing even the prototype sums to millions. FEA is not only a technically viable option to manufacture high-ticket products but also it is one of the most economical ways to deal with product complications, malfunction and future system failures.

The process of modelling the probable real life intricacies on a piece of paper or digitally and combining all the PDEs abiding by the law of physics is the best way to find a solution to an unknown problem. In this competitive era, the factors influencing design are changing rapidly. What these factors used to be decades ago aren't similar today.

Moreover, the complications in bringing the complex designs to life are also evolving. Hence, putting FEA forward to optimise tangled designs is preferred by companies in most domains. It helps to come up with a splendid end product with zero flaws. Datum Advanced Composites is a renowned engineering company in India that offers finite element analysis services that helps enterprises create the product of their dreams.

Comments

Post a Comment